4 Color process vs Spot color printing

One of the most crucial decisions you’ll have to make as a designer is what colors to use in your design. When color accuracy and consistency are critical to your design, you should use spot color printing.  When deciding whether to utilize spot colors or process colors, there may be a lot of uncertainty. Knowing the difference between the two can be the difference between a decent and a great final result. This article discusses the key differences between spot and process colors and why and when to use spot colors in your design.

When deciding whether to utilize spot colors or process colors, there may be a lot of uncertainty. Knowing the difference between the two can be the difference between a decent and a great final result. This article discusses the key differences between spot and process colors and why and when to use spot colors in your design.

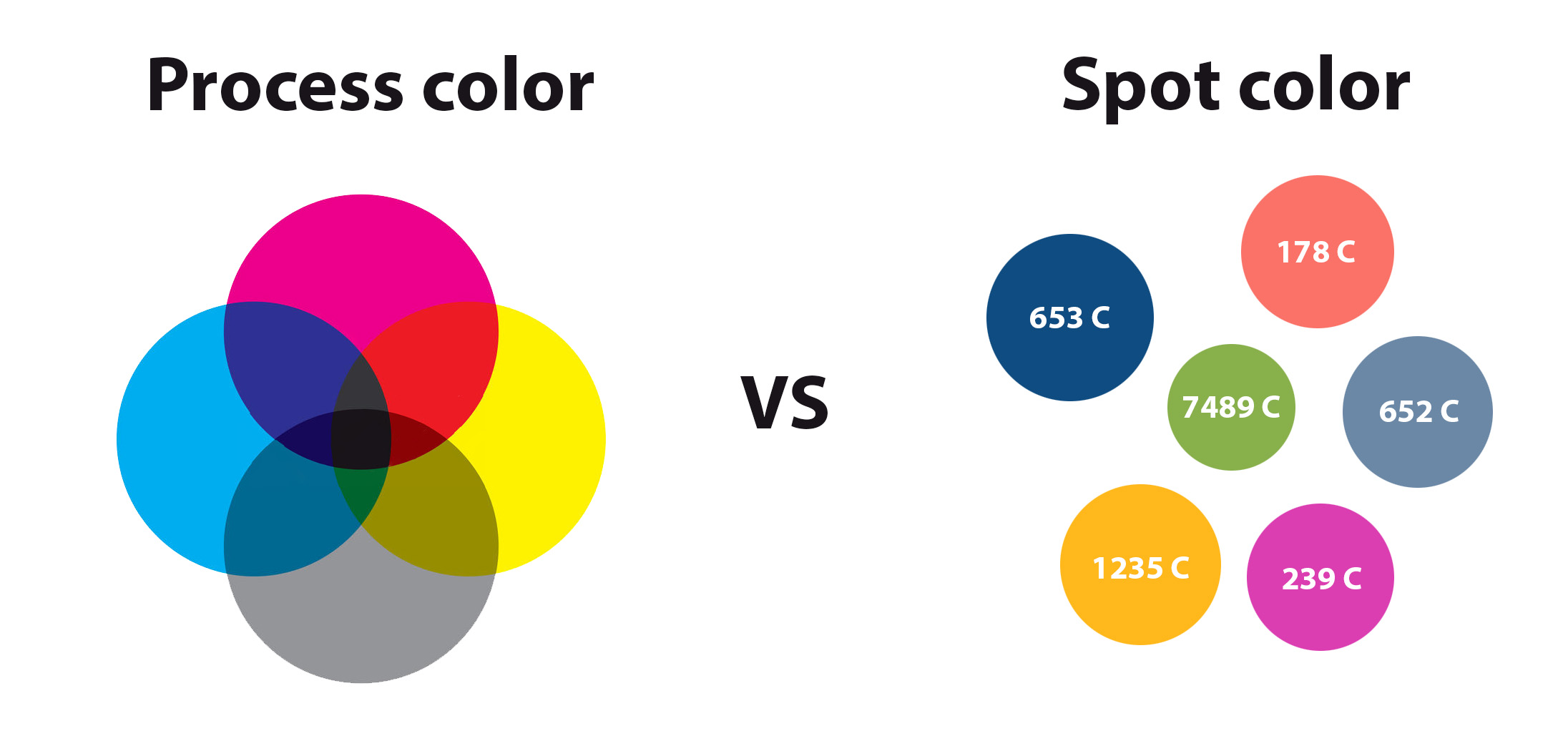

Spot vs. Process

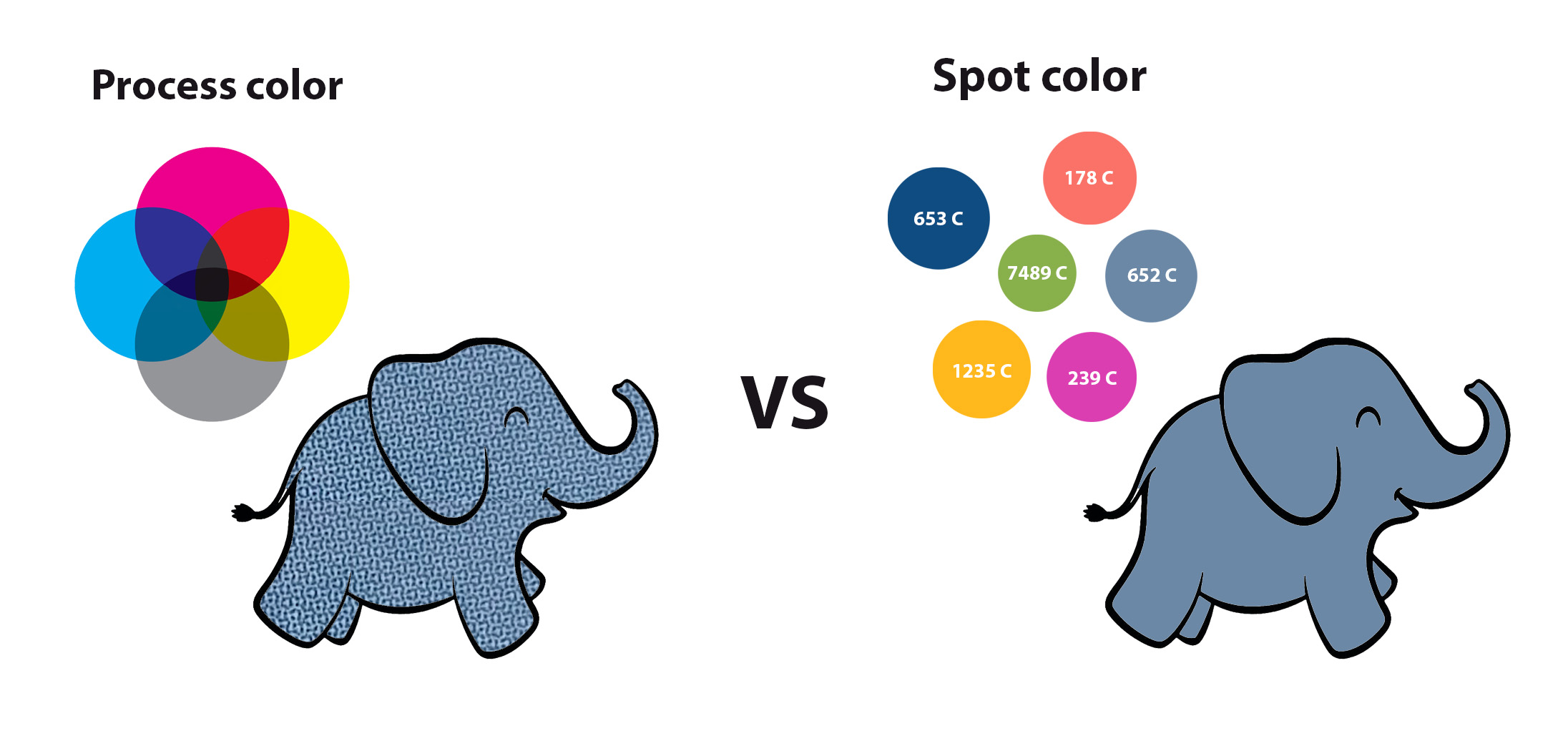

In the world of printing, there are two main types of color printing: spot color and process color. Spot color is a single color that is printed using its own dedicated plate. In contrast, CMYK process color is created by mixing multiple colors together in order to produce the desired effect. Each method has its own advantages and disadvantages, so choosing the right one for your project is essential.

Spot color printing is ideal for projects that only require a few colors or when you need an exact match to a specific color (like a company logo). The downside of spot color printing is that it can be more expensive than process color since each color requires its own plate.

CMYK printing was first used in 1906 and to this day, it is the most commonly used method. It’s less expensive and offers a wider range of colors than spot colors. CMYK Process color printing is perfect for projects that require many different colors or when you need a wide range of color options.

The downside of process color printing is that it can be less accurate than spot color since the colors are created by mixing together multiple inks, while the downside of spot printing, is that you might need a lot of different base pigments in very specific amounts, so it’s not always very efficient.

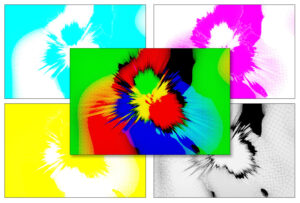

Process printing might require some additional preparation steps. For example, the page layout will have to undergo some sort of color separation procedure. It is a technical process of separating the colors in an image into 4 channels of cyan, magenta, yellow and black.

Process printing might require some additional preparation steps. For example, the page layout will have to undergo some sort of color separation procedure. It is a technical process of separating the colors in an image into 4 channels of cyan, magenta, yellow and black.

This is done for printing purposes so that each color can be printed one at a time. See the image on the right that illustrates separated layers and the final outcome of CMYK based print.

Usually screen printing will require color separation to obtain CMYK values, which are necessary for creating accurate color schemes. This process of separating colors into CMYK values can be done in Photoshop, Illustrator, or InDesign.

The Process color and Spot color are two different ways of forming the final result. Both of these methods are slightly different but could be impeccable and faultless when carried out correctly.

So, which one should you use for your project? It depends on your specific needs. If color accuracy and consistency are critical, you should use spot color. Process color might be better if you need a wide range of color options.

So, which one should you use for your project? It depends on your specific needs. If color accuracy and consistency are critical, you should use spot color. Process color might be better if you need a wide range of color options.

Pantone Spot Color

Pantone spot color is a color model used in offset printing. It is also known as the PMS color system and was developed by Pantone Inc. in 1962. The system consists of 14 colors, which can be mixed to produce thousands of different colors. The Pantone colors are identified by a code typically printed on a swatch card. These cards can be used to match colors when printing on different types of paper or other materials.

Pantone spot color is a color model used in offset printing. It is also known as the PMS color system and was developed by Pantone Inc. in 1962. The system consists of 14 colors, which can be mixed to produce thousands of different colors. The Pantone colors are identified by a code typically printed on a swatch card. These cards can be used to match colors when printing on different types of paper or other materials.

Pantone colors are often used for corporate identity programs, product branding, and packaging. They can also be used to create matching colors between different print jobs. Using the correct ink type and drying method is vital to avoid color shifting when using spot colors. The most popular collections of Pantone spot colors are Pantone solid coated and Pantone solid uncoated, but also Pantone has a CYK based collection which is named Pantone CMYK color guide, the key difference between these collections is that the later one is readily available for CMYK process usage. As opposed to previously mentioned, spot color collections where you might need to use online conversion tools to obtain each individual CMYK color code.

Why Use Spot Color?

There are a few reasons why spot color may be used in offset printing:

* Spot color can be used to create special effects or to add visual interest to a design.

* Spot color can be used to ensure that a particular color is reproduced accurately and consistently.

* Spot color may be used when a design requires colors that cannot be reproduced using the four process colors (cyan, magenta, yellow, and black).

When to Use Spot Colors

There are a few situations when it’s best to use spot colors in your design:

– When you need an exact match to a specific color (like a company logo)

– When you only need a few colors

– When color accuracy and consistency are critical

– When a printing job requires special effects like fluorescent colors or a metallic look

– When printing jobs require coverage over a large area

If any of these apply to your project, then spot colors might be the way to go.